Pipelines are all around us; they transport water and natural gas to our homes and take away excess water and sewage. But how do fluids move through these vast pipeline networks?

Let's take a look.

A pipe is a hollow cylinder made out of a material like metal, plastic, wood, or even clay, that is used to move substances that flow, like liquids and gases. When several pipes are connected in a series to transport materials over long distances, the resulting structure is called a pipeline.

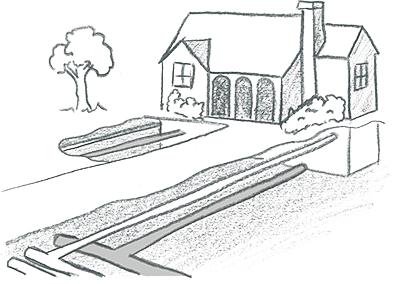

Pipelines are everywhere; in our walls, floors, streets, fields and prairies, and along rivers, lakes, and seas. They travel underground and over ground, and are used to transport many different products. For example, complex systems of pipelines and plumbing bring clean water and natural gas to our homes and take away excess water and sewage.

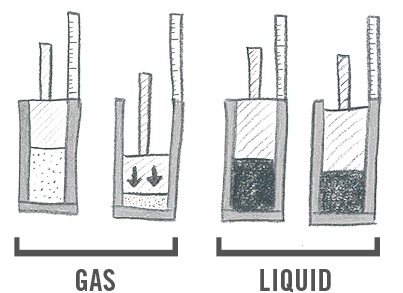

Fluids are liquids and gases that continually flow when a force is applied to them. But different fluids react to force differently; they can be compressible or incompressible, which is the big difference between liquids and gases. Liquids are generally incompressible, meaning they don't change volume much in response to pressure change, whereas gases are compressible so will change volume in response to a change in pressure. And whether or not a fluid is compressible will change how it flows when force is applied to it in a pipe.

There are basically two ways to move fluids through a pipe. One way is to tilt the pipe so it flows downhill and gravity provides the force to move the fluids. The second way is to make the pressure at one end of the pipe greater than the pressure at the other end. This pressure difference creates force, which pushes the fluid constantly towards the lower pressure area.

Now that we know how to get a fluid flowing, let's look at what might slow down fluids in the pipeline.

How fluids flow and the amount of force required to move them is dependent on a range of factors like the diameter of the pipe, the viscosity of the fluid, and the roughness of the inside of the pipe, just to name a few. In fact, even the contact of the fluid with a smooth surfaced pipe can cause the fluids to slow down due to friction.

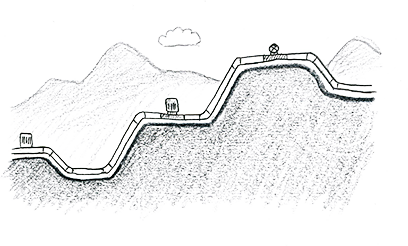

Gravity is another force that often affects the movement of a fluid travelling through a pipeline. When travelling downhill, gravity helps move the fluid, but when travelling uphill, gravity is working against the flow and must be overcome. And overcoming this force uses some of the pressure difference that's moving the fluid.

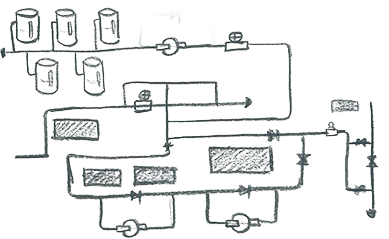

In order to overcome these forces, pumps for liquids and compressors for gases are positioned at regular intervals along the length of a pipeline to increase the pressure and manage the flow of the fluids in the pipeline. Pump and compressor stations are strategically located to help push the product through sections of pipeline where various forces act against the pressure difference.

Pumps or compressor stations are strategically located to help push the product through a section of pipeline where various forces act against the pressure difference such as going over a mountain range where gravity works against the pressure difference.

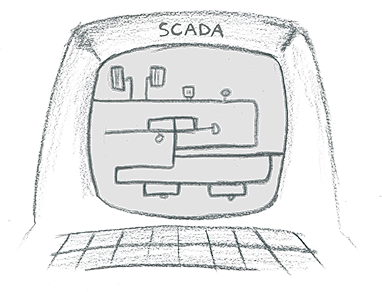

Pipelines are monitored constantly, 24 hours a day, 7 days a week, 365 days a year, by pipeline control centre operators. A variety of instruments and equipment provide them with information about volume, pressure, temperature and pump/compressor data that reflects the movement of fluids in the pipeline along its entire length. The pipeline control centre operator uses all this information to make sure the product is flowing and to determine if any further action needs to be taken.

Some pipeline control centre operators work in a control centre, where the information from sensors installed along the pipeline route is sent. One such system is called SCADA (Supervisory Control and Data Acquisition). The SCADA system is unique in that it allows pipeline control centre operators to remotely control pipeline flow by starting and stopping pumps and compressors. In this way, pipeline control centre operators can keep fluids flowing through the pipeline at the desired rate or, if necessary, control valves to completely stop the flow from a section of pipe.

The SCADA system also allows pipeline control centre operators to remotely control pipeline flow by starting and stopping pumps and compressors. In this way, pipeline control centre operators can keep fluids flowing through the pipeline at the desired rate or if necessary, control valves to completely stop the flow from a section of pipe.

- Home

-

Help

How to Use

Here is your chance to explore how fluids flow in whatever way you want. There are 5 sections that will help you learn about how fluids move through a pipeline.

The Basics

Want to know more about flow? Head to the basics section and get the scoop on pressure.

Experiment

Here is your chance to experiment and move fluids for yourself. Try out different methods to control the flow of fluids.

Challenge

Now it's time to apply all your knowledge. Complete the challenge and see how you stack up.

Test Yourself

Think you know it all? Test yourself to see if you are the real deal! You have three questions to answer, but if you're feeling brave you can add some more.

If you're ever unsure of what a word means, check out the definition in the glossary! You can also click on any highlighted word to take you straight there.

-

Teacher Info

Overview

Pipeline Pressure provides students an opportunity to explore a science topic in their own way, at their own pace.

The four sections of the tool have been designed to guide students through the process of understanding fluid flow and pipeline pressure, and let them put that information into practice. Students will gain knowledge of the topic by reading the basics, experimenting without consequence to learn the techniques, applying their knowledge to solve a challenge, and assessing their knowledge with a self-test. A comprehensive glossary also lets them check definitions at any time along the way.

This tool provides a way to teach the elements of the science unit, but also puts science into perspective with real world examples, challenges students to use technology to further their understanding of science, and engages them with a wide range of activities.Curriculum

Grade 8 – Mix and Flow of Matter

SLE #4 - Identify, interpret and apply technologies based on properties of fluids.

-

Glossary

- Compressible

- The measure of the relative volume change of a fluid or solid in response to pressure.

- Compressor

- Compressors are used to increase the pressure of gases, such as natural gas. These pressure differences are required to move gases through their containers. In pipelines, compressor stations are strategically placed along the length of the pipeline to maintain required flow rates.

- Fluids

- A substance that has no fixed shape and yields easily to external pressure. Gases and liquids are examples of fluids.

- Force

- A force is anything that causes an object to undergo a certain change concerning its movement, direction, or geometrical construction.

- Friction

- The resistance that a moving object encounters when in contact with another object.

- Gravity

- The force that attracts a body toward the center of the earth, or toward any other physical body having mass.

- Incompressible

- Incapable of or resistant to compression.

- Pipeline Control Centre Operator

- Pipeline Control Centre Operators monitor and manage pipeline activities for large regions from one centralized control centre. They monitor flow, product quality, and line balance, and manage them by operating control valves, compressors, and pumps remotely.

- Pressure

- Pressure is the force exerted on a given area expressed in Pascals (Pa) or in pounds per square inch (PSI). In pipelines, oil and natural gas transported within a pipeline exert pressure on the pipe walls.

- Pump

- A pump is a mechanical device used to increase the pressure of a liquid in a container, such as oil in a pipeline. This increased pressure is used to push the liquid through the container towards an area of lower pressure.

- SCADA

- SCADA is a pipeline control system. It gathers information from the pipelines and transmits it to a control facility where the data can be monitored and analyzed. The operator can then issue commands to remote sites to perform actions like opening and closing valves, or starting and stopping pumps or compressors.

- Valve

- A valve is a mechanical device installed in a pipeline and opened or closed to control the flow of fluids. They are most often placed where they can close to stop the flow of fluid, and allow sections of the pipelines to be separated for repair. Some valves are also used to control the pressure and/or flow rates in pipelines.

- Credits

Your overall score

Read each slide to earn maximum points.

Explore the simulator. Try out all the different combinations to earn maximum points.

Successfully complete all 5 levels to earn maximum points.

Earn 5 points for every question correctly answered.